capsule filling machine working principle

Working Principle of Dosator Type Capsule Filling Machine to Filling. Every machine has its own working method.

Automatic Capsule Filling Machine Capsule Filling Machine Your Best Online Resource About Capsule Fillers

VitaMondo A Wide Range of Organic Herbal Extracts Vitamins Antioxidants Supplements.

. These are the most crucial parts of a capsule filling machine. - Thursday June 6 2019. The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process.

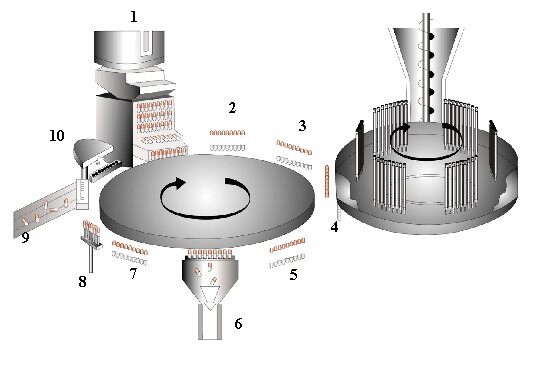

Again there are many manual encapsulator machines available in the market with varying production capacities. Below is an image showing how a dosator capsule filling machines works Ill explain this shortly. During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous rotation The filling volume of the capsule is mainly determined by the volume of the measuring disc hole.

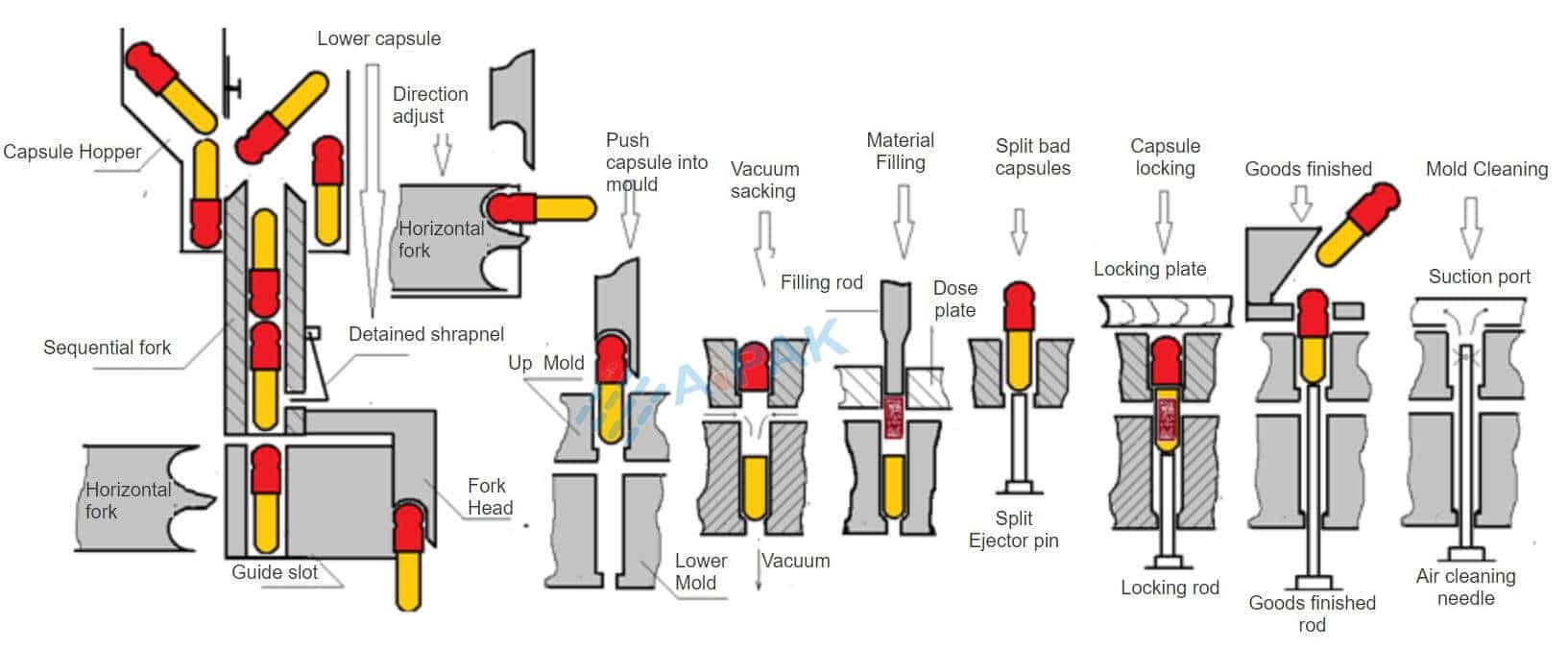

After rectification the capsule tray is moved to the capsule filling station and the caps and bodies of the capsule are separated using a vacuum divider. Ad Most affordable capsule machine on the market this is great for making your own vitamins. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding plate one by one.

You can also look for the automatic capsule filling machine. The trays can hold many capsules at a time to make the process fast. The machine that can greatly improve production efficiency and reduce labor costs.

Dosator capsule filling machine. Turn ingredients into convenient softgels. Automatic Capsule Filling Machine Working Principle.

Once the capsule separation is done the cap and the body are transferred to their respective stations. These personal capsule filler machines allow people to fill their capsules with the necessary medication. Automatic capsule filling machine is a fully automatic capsule filling machine with which capsule separation filling and locking can be done automatically.

Even though the process seems simple and straightforward any failuremalfunction in any of the tamping pins may cause serious loss high rate of capsule rejection. Ad VitaMondo Dietary Supplements with Volume Discounts and Free Shipping to 150 Countries. Division of capsule caps from their bodies.

The positioning of colourless translucent capsules in the capsule filling tray. The body of the capsule is transferred to the filling station where the active ingredients. As you can see it involves only three major steps that you can master easily without any rigorous training.

Trusted China Suppliers Verified by SGS. Working Principle of A Capsule Filling Machine. The machine can greatly improve production efficiency and reduce labor costs.

NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole. In the capsule hop per the hollow capsule the main board moves up and down the capsule into the capsule groove. Most encapsulating machines use either the tamping pin or dosator technology.

Rearrange the caps and bodies. In most machines empty capsules and place in trays a bottom and top tray. You can then process the Softgel capsules further by drying polishing or printing.

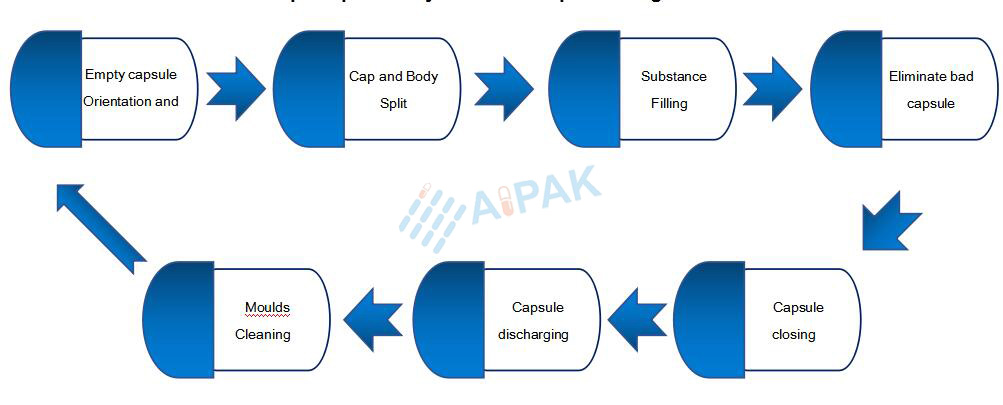

The capsule filling machine works in a step-by-step process that is as mentioned below. Personal capsule filling machines is for small scale production and utilization. Ad Quality Capsule Filling Machine with Competitive Price.

Automatic capsule filling machine working principle. On the other hand professional capsule fillers are used in pharmaceutical industries at large scale production with high efficiency. Second the vacuum system separates the empty capsule to avoid damage.

Easy to use capsule maker. Filling up the capsule body with pharmaceutical ingredients. The capsule filling machine working principle is usually a very simple and straightforward process.

The capsule filling machine is an automatic capsule filling machine by which the separation filling and sealing of capsules can be carried out automatically. In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored. The working principle of a manual capsule filler is simple.

It has 9 holes turning out a highest output of 1200 capsulesminute. Regardless of the type and model of your auto or semi-automatic capsule filling machine a vacuum system is vital. However for the scope of this article Ill focus mainly on the dosator type capsule filling machines.

First the vacuum loader connects the capsule loading device to the capsule hopper and material loading port to the material hopper.

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine High Speed Capsule Filler

Powder Filling Drug Absorption Pharmacological Sciences

Semi Automatic Capsule Filling Machine Saintytec

Filling Machines Their Working Principles

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Automatic Capsule Filling Machine High Speed Capsule Filler

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

How Different Types Of Capsule Filling Machine Work

Tamping Pin Type Capsule Filling Machine Working Principle

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Hard Shell Capsule Filling Machines Basicmedical Key

Automatic Capsule Filling Machine Working Principle Ipharmachine